Key Highlights:

- Gas post hole diggers create deep, narrow holes for applications like fence posts, tree planting, and utility installation.

- They utilise a rotating drill bit with sharp blades, suitable for various soil types and conditions.

- Key components include a throttle for speed control, different drill bit sizes, and safety features for operator protection.

- Proper site preparation involves clearing debris, marking underground utilities, and checking equipment condition.

- In 2022, construction saw 142 fatalities from caught-in or compressed-by accidents, highlighting the need for safety measures.

- Effective digging techniques include starting at low speed, applying consistent throttle pressure, and regularly removing excess soil.

- Gas post hole diggers can significantly increase productivity, achieving 250-400 openings in an 8-hour day compared to 25-40 manually.

- Cost efficiency improves after creating 300-500 openings, reducing expenses per opening to ₹15-25.

- Regular maintenance, including cleaning, checking fluid levels, and inspecting for wear, extends the lifespan of gas post hole diggers to 5-10 years.

Introduction

Gas post hole diggers represent a significant advancement in efficient excavation, turning challenging digging tasks into manageable projects. By mastering the functionality and techniques associated with these powerful machines, operators can greatly enhance productivity while prioritizing safety on the job site. The challenge, however, extends beyond merely understanding how to operate this tool effectively; it also involves navigating the essential safety protocols and maintenance practices that are crucial for its success.

What strategies can elevate the use of gas post hole diggers from ordinary to exceptional?

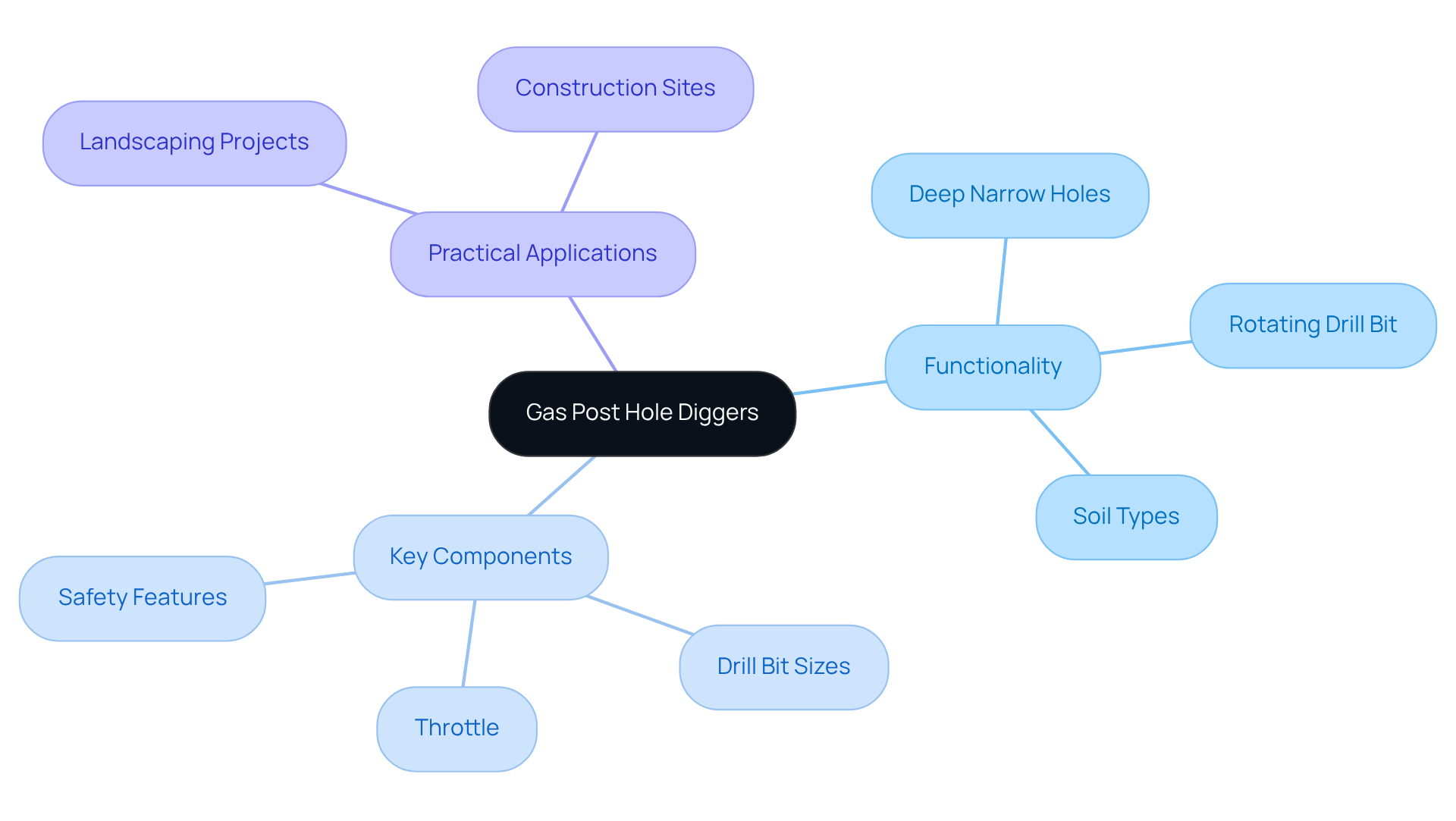

Understand the Functionality of Gas Post Hole Diggers

Gas post hole diggers are robust machines specifically engineered to create deep, narrow holes in the ground. These machines are essential for various activities, including setting fence posts, planting trees, and installing utility poles. They use a gas post hole digger to propel a rotating drill bit into the soil. The drill bit, equipped with sharp blades, efficiently cuts through different soil types, ensuring effective digging even under challenging conditions. Key components include:

- A throttle for speed regulation

- Various drill bit sizes for different openings

- Crucial safety features designed to protect the operator

Understanding the operation of gas-powered excavators is vital for improving efficiency and minimizing hazards. Construction professionals often highlight the significance of selecting the appropriate auger bit size based on project requirements, as this choice can greatly influence both efficiency and effectiveness. The practical applications of a gas post hole digger are evident in landscaping projects where precise placement is critical, as well as in construction sites where rapid installation of supports is necessary. By mastering the functionality of these tools, operators can boost productivity and ensure successful project outcomes.

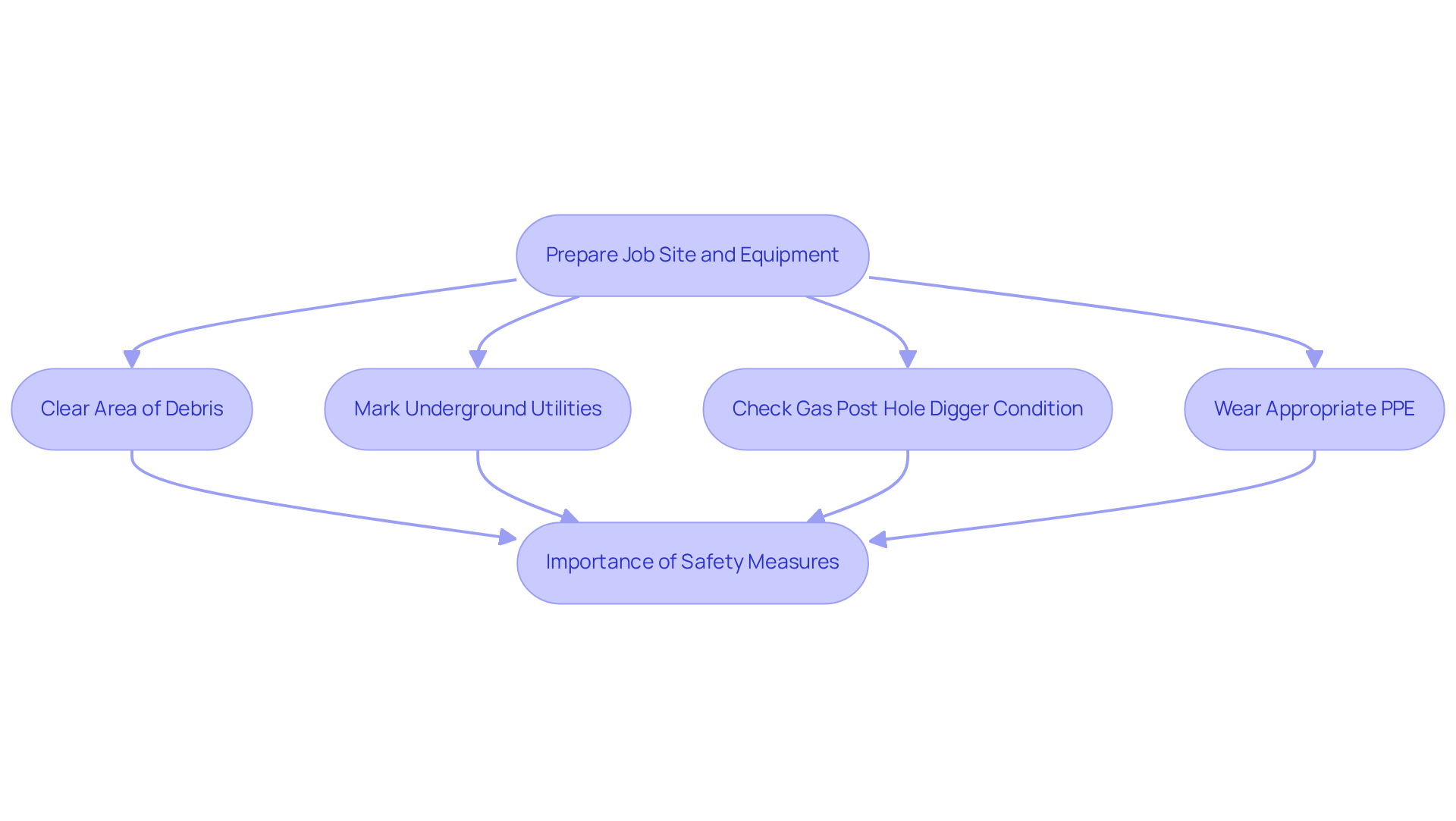

Prepare the Job Site and Equipment for Safe Operation

Before using a gas post hole digger, it is essential to thoroughly prepare both the work area and the tools. Begin by clearing the area of any debris, rocks, or vegetation that could obstruct the digging process. It is also important to mark the location of underground utilities to prevent damage during excavation. Ensure that the gas post hole digger is in good working condition by checking fuel levels, inspecting the drill for wear, and tightening any loose bolts. Additionally, wearing appropriate personal protective equipment (PPE), such as gloves, goggles, and sturdy footwear, is crucial for safeguarding against potential injuries. Following these preparatory steps enhances safety and efficiency during the digging operation.

In 2022, there were 142 fatalities from caught-in or compressed-by accidents in construction, underscoring the necessity of implementing safety measures. The SafetyNow method has been shown to reduce accidents and incidents by an average of 47%, highlighting the significant impact of effective safety training. A cautionary example is the Tilt-Up Wall Panel Incident, where inadequate safety measures led to a fatality, reinforcing the importance of proper PPE usage and thorough site preparation.

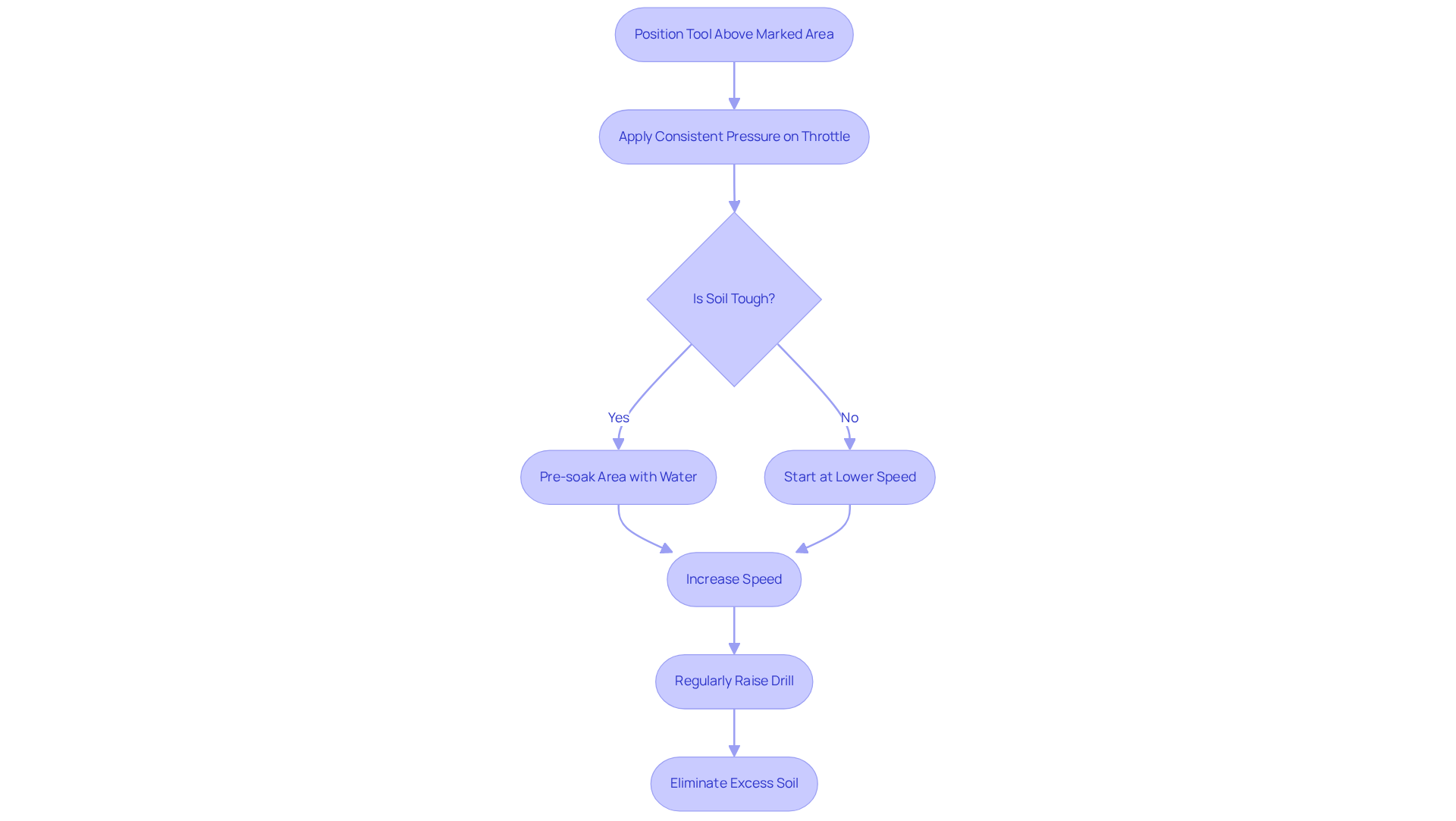

Implement Effective Techniques for Digging

To maximize the efficiency of the gas post hole digger, users should adopt several effective digging techniques. Start by positioning the drilling tool directly above the marked area and applying consistent pressure on the throttle to initiate digging. It is advisable to begin at a lower speed, allowing the tool to gradually penetrate the soil. Once the bit has created an opening, increase the speed to expedite the digging process. Regularly raising the drill out of the pit helps eliminate excess soil and prevents clogging, which can hinder operations.

For particularly tough soil conditions, pre-soaking the area with water can soften the ground, making it easier to dig. These techniques not only enhance digging efficiency but also reduce wear on the equipment, ensuring longevity and reliability in your projects. Using a gas post hole digger, one operator can accomplish the work of more than ten workers, creating 250-400 openings in an 8-hour workday compared to only 25-40 openings done manually. This significant time savings underscores the value of employing gas-powered augers in construction tasks.

Furthermore, the efficient expense per opening using a digging tool can reduce to ₹15-25 after creating 300-500 openings, offering substantial financial advantages for project managers.

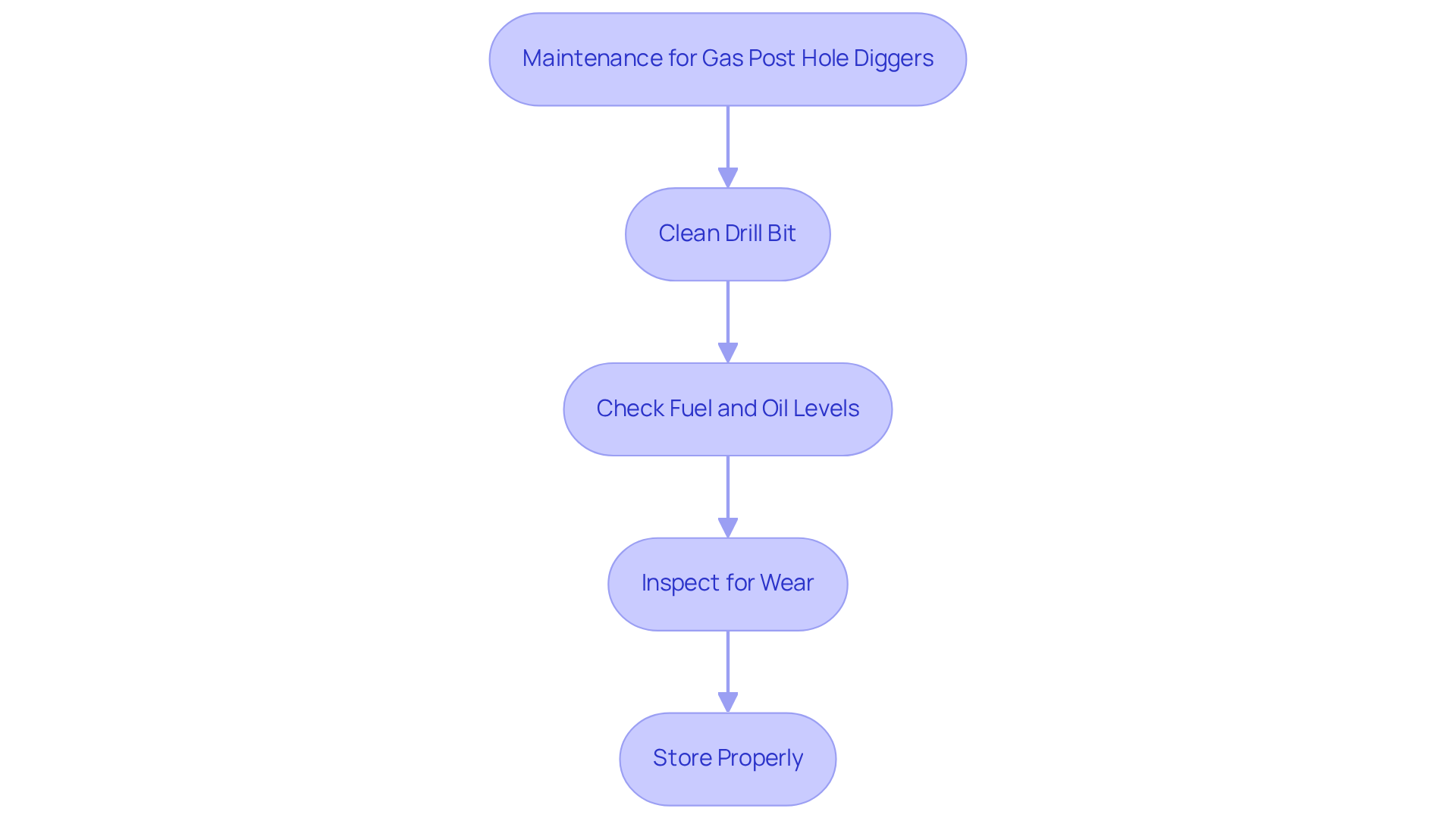

Maintain Equipment for Longevity and Reliability

Regular maintenance of gas post hole diggers is crucial for maximizing their lifespan and ensuring dependable performance. With proper care, these drilling tools can last between 5 to 10 years, depending on usage and maintenance practices. After each use, it is crucial to clean the drill bit thoroughly to remove soil and debris, which can lead to rust and corrosion. As Cole Blackwell, an attachment sales manager for JCB, emphasizes, "Routine maintenance not only keeps a drill working efficiently but also maximizes return on investment by reducing repair costs and extending its service life."

Checking and maintaining fuel and oil levels is vital for optimal engine function. Replacing these fluids as necessary helps prevent operational issues. Regular inspections for signs of wear, such as dull blades or bent shafts, are critical, as worn components can significantly reduce drilling efficiency and increase strain on the equipment. Additionally, storing the digger in a dry, secure location protects it from environmental damage. Blackwell further notes, "Proper storage extends auger lifespan," highlighting the importance of preventing moisture exposure.

By implementing these maintenance practices, users can ensure their equipment remains in optimal condition, ready for future projects.

Conclusion

Gas post hole diggers are essential tools that simplify the process of creating precise holes for various construction and landscaping projects. Mastering their functionalities, safety protocols, and maintenance practices enhances efficiency and ensures the safety and longevity of the equipment. A solid understanding of how these machines operate and the importance of preparation can significantly impact project success.

Key insights include:

- The necessity of proper site preparation to avoid accidents

- Effective techniques for maximizing digging efficiency

- The critical role of routine maintenance in extending the life of the digger

Emphasizing safety measures, such as using personal protective equipment and marking underground utilities, helps prevent injuries and costly damages. Additionally, implementing efficient digging methods can lead to substantial time and cost savings, showcasing the advantages of using gas-powered tools over manual labor.

Ultimately, mastering gas post hole digger techniques is not just about improving productivity; it reflects a commitment to safety and quality in every project undertaken. By adopting these best practices, operators can ensure they are equipped to handle the demands of their tasks while safeguarding their investment in this powerful equipment. Embracing these techniques and prioritizing safety will lead to successful outcomes in all your digging endeavors.

Frequently Asked Questions

What is a gas post hole digger?

A gas post hole digger is a robust machine designed to create deep, narrow holes in the ground, essential for activities like setting fence posts, planting trees, and installing utility poles.

How does a gas post hole digger work?

It uses a gas-powered engine to propel a rotating drill bit into the soil, with the drill bit equipped with sharp blades that efficiently cut through various soil types.

What are the key components of a gas post hole digger?

Key components include a throttle for speed regulation, various drill bit sizes for different openings, and crucial safety features designed to protect the operator.

Why is it important to understand the operation of gas post hole diggers?

Understanding their operation is vital for improving efficiency and minimizing hazards during use.

How does the choice of auger bit size affect the use of a gas post hole digger?

Selecting the appropriate auger bit size based on project requirements greatly influences both the efficiency and effectiveness of the digging process.

In what types of projects are gas post hole diggers commonly used?

They are commonly used in landscaping projects where precise placement is critical and in construction sites where rapid installation of supports is necessary.

What benefits do operators gain from mastering the functionality of gas post hole diggers?

Operators can boost productivity and ensure successful project outcomes by mastering the functionality of these tools.

List of Sources

- Understand the Functionality of Gas Post Hole Diggers

- Global Post Hole Digger Market Key Players and Market Share 2025-2032 (https://statsndata.org/report/post-hole-digger-market-231937)

- Auger Drilling Market Trends, Share and Forecast, 2025-2032 (https://coherentmarketinsights.com/industry-reports/auger-drilling-market)

- Post-hole Auger Market, Global Outlook and Forecast 2025-2032 (https://statsmarketresearch.com/global-posthole-auger-forecast-market-8060460)

- Post Hole Borer Market Demand Forecast with 12% CAGR Growth from 2025 to 2032 (https://linkedin.com/pulse/post-hole-borer-market-demand-forecast-12-cagr-growth-hmdwe)

- Earth Augers Market Size, Competitors & Forecast to 2028 (https://researchandmarkets.com/report/earth-auger?srsltid=AfmBOoqpzoCNygUJPm_BI0MXUeMcnKVWR3HLZ-KqtHpDAK1ybWEqIKfb)

- Prepare the Job Site and Equipment for Safe Operation

- Top 100 Inspirational Workplace Safety Quotes (https://damotech.com/blog/inspirational-quotes-warehouse-safety)

- eTool : Construction - Struck-By | Occupational Safety and Health Administration (https://osha.gov/etools/construction/struck-by)

- Heavy Equipment Operation Stats & Facts (https://bhhcsafetycenter.com/heavy-equipment-operation-stats-facts?print=pdf)

- Personal Protective Equipment (PPE) Statistics To Know In 2025 (https://oshagear.com/blog/ppe-statistics)

- Construction Industry Injuries and Fatalities on the Rise (https://usclaims.com/educational-resources/construction-industry-injuries-and-fatalities-on-the-rise)

- Implement Effective Techniques for Digging

- Post-hole Auger Market, Global Outlook and Forecast 2025-2032 (https://statsmarketresearch.com/global-posthole-auger-forecast-market-8060460)

- 119 Construction Quotes that Hit the Nail on the Head | BigRentz (https://bigrentz.com/blog/construction-quotes?srsltid=AfmBOoraREsdsbNOJqJ2tl6paY-cGj70cXM_2ZhBqzOoCSiIgU-IHc7U)

- Post Hole Digger vs Manual Digging: ROI Analysis | MMS Industries (https://mmsindustries.com/compare/post-hole-digger-vs-manual-digging)

- 40 Construction Quotes to Motivate Your Team (https://projectmanager.com/blog/construction-quotes)

- 10 Construction Quotes to Inspire Your Project (https://horstconstruction.com/10-wise-construction-quotes-to-inspire-your-next-project-2)

- Maintain Equipment for Longevity and Reliability

- APIE PRODUCT KNOWLEDGE—What is the life of an auger? – APIE FOUNDATION EQUIPMENT(CHINA) LIMITED (https://apiepiling.com/apie-product-knowledge-what-is-the-life-of-an-auger)

- What is the average lifespan of Auger Wear Parts? - Blog (https://tx-industries.com/blog/what-is-the-average-lifespan-of-auger-wear-parts-664413.html)

- Maximizing Auger Attachment Longevity with Proper Maintenance (https://compactequip.com/attachments/maximizing-auger-longevity-with-proper-maintenance)

- 25 Maintenance Stats, Trends, And Insights For 2026 (https://getmaintainx.com/blog/maintenance-stats-trends-and-insights)

- The Latest Statistics from the Maintenance Industry [2025] (https://getsockeye.com/blog/maintenance-statistics)