Overview

Maximizing your bridge saw rental begins with a thorough assessment of project specifications.

Selecting the right saw based on material and thickness is crucial.

Understanding rental terms and maintenance responsibilities cannot be overlooked.

Careful selection and adherence to best practices, such as inspecting equipment and providing feedback post-rental, significantly enhance operational efficiency and safety.

Ultimately, these steps lead to superior project outcomes.

Engage with us today to ensure your next project achieves its fullest potential.

Key Highlights:

- Assess project specifications, including the materials and their thickness, to choose the right bridge saw.

- Ensure compatibility between the saw and the required blade size and type for effective cutting.

- Select a saw with adequate motor power for cutting dense materials efficiently.

- Evaluate the saw's cutting capacity, including maximum depth and angle, for versatility.

- Consider the portability of the saw if frequent relocation is necessary for the project.

- Understand rental terms such as lease duration, damage liability, maintenance responsibilities, and insurance options.

- Inspect the rental equipment thoroughly before use to ensure safety and functionality.

- Wear appropriate protective gear to prevent injuries during operation.

- Maintain proper cutting speed for different materials to avoid damage and ensure efficiency.

- After rental, clean the equipment, inspect for damage, provide feedback to the leasing company, and evaluate the borrowing experience.

Introduction

Navigating the world of bridge saw rentals can be a daunting task, particularly when precision and efficiency are paramount in cutting materials such as granite or marble. It is essential to understand the nuances of selecting the right equipment, adhering to rental agreements, and implementing best practices. These factors can significantly enhance project outcomes. However, many renters overlook critical aspects that can lead to costly mistakes and inefficiencies.

So, what are the essential strategies that can transform a bridge saw rental experience from merely adequate to exceptionally successful?

Choose the Right Bridge Saw for Your Project Needs

Selecting the appropriate bridge saw rental for your project requires careful consideration of several key factors that can significantly impact your outcomes.

Project Specifications: Begin by assessing the materials you will be cutting—granite, marble, or tile—and their thickness. Each saw is engineered for specific materials and thicknesses, which directly affects cutting efficiency and quality.

Blade Size and Type: Ensure compatibility between the saw and the required blade size and type for your task. Larger blades can handle thicker materials but may require more power to operate effectively.

Motor Power: A robust motor is essential for efficient cutting, especially with dense materials. Opt for saws with higher horsepower ratings to meet the demands of heavy-duty applications.

Cutting Capacity: Evaluate the saw's maximum cutting depth and angle capabilities to ensure they align with your specifications. This guarantees versatility in handling various cutting tasks.

Portability: If your project necessitates frequent relocation of the saw, consider its weight and transportability. Some models are designed with wheels for enhanced mobility, making them easier to maneuver on job sites.

Furthermore, while bridge cutting tools necessitate a considerable initial expenditure, they offer savings through decreased waste and lower labor expenses, making them a financially viable option over time. Choosing high-quality tools is critical to prevent costly errors and wasted resources, as low-quality machines can lead to inefficiencies.

Incorporating insights from construction professionals can also guide your selection process. For example, a manager might state, 'Selecting the appropriate bridge saw is one of the most crucial choices a stone fabrication company can undertake.' Understanding the average cutting capacity of bridge saw rental options for granite and marble can provide valuable performance metrics to inform your decision.

By thoroughly evaluating these factors and considering the potential pitfalls of selecting unsuitable machines, you can choose a bridge saw rental that meets your project specifications, leading to superior results and efficient operation.

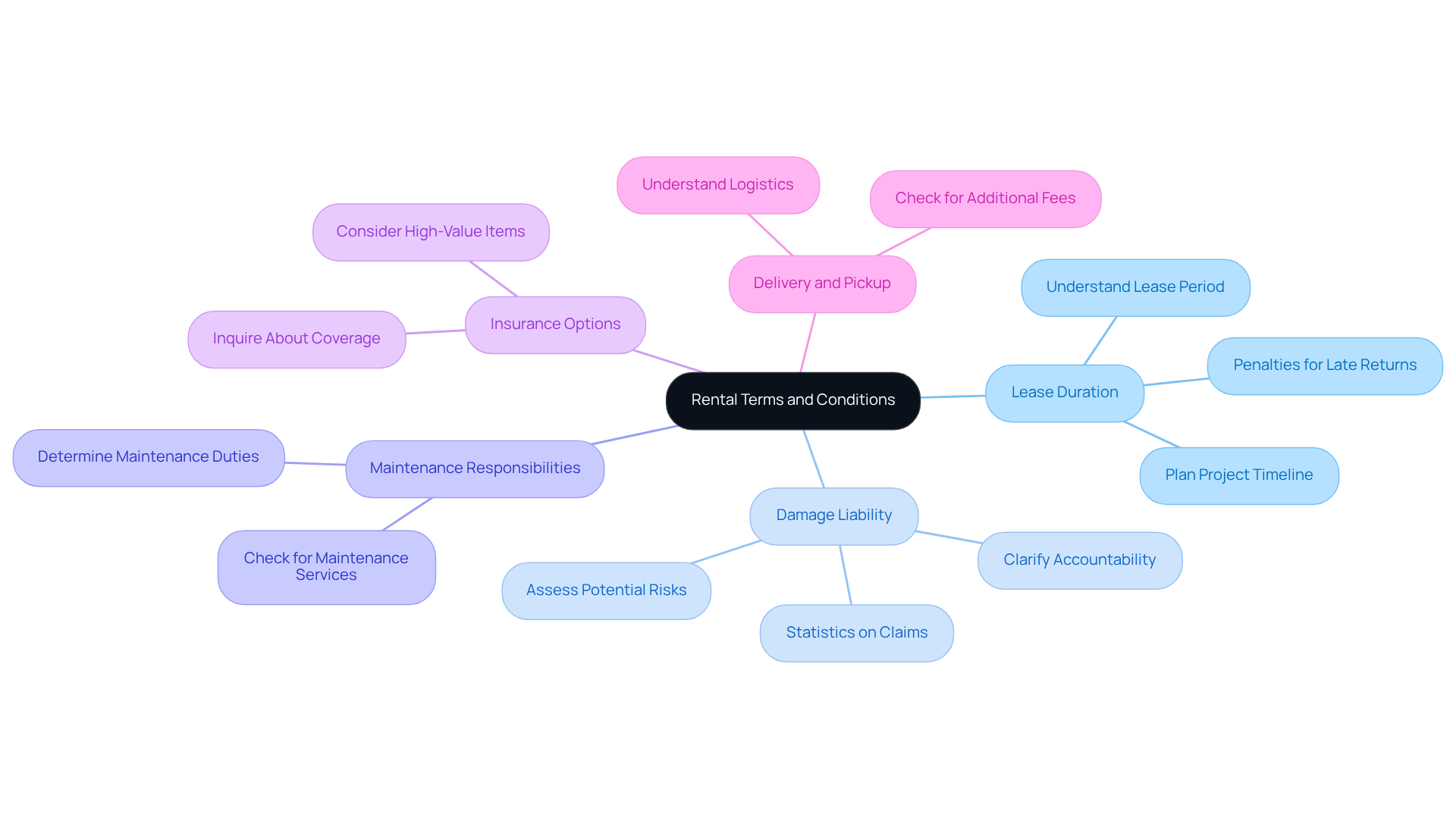

Understand Rental Terms and Conditions

Before proceeding with a bridge saw rental, it is crucial to thoroughly review the rental terms and conditions to ensure a smooth experience.

Lease Duration: Clearly understand the lease period and any penalties for late returns. Planning your project timeline effectively can help avoid additional charges, which can significantly impact your budget.

Damage Liability: It is essential to clarify who is accountable for damages incurred during the leasing period. Many agreements stipulate that renters must cover repair costs for any damage, making it vital to assess potential risks before signing. Statistics suggest that damage liability claims are a frequent concern in machinery leases, with the concrete saw leasing market anticipated to expand from US$ 107.9 million in 2022 to US$ 191.2 million by 2033. This underscores the growing importance of comprehending leasing contracts.

Maintenance Responsibilities: Determine whether you are responsible for maintaining the equipment during the lease period. While some leasing companies provide maintenance services, others may require you to handle upkeep, which can influence your overall project expenses.

Insurance Options: Inquire if the rental company provides insurance options to cover potential damages or accidents. This can provide peace of mind, particularly for high-value items such as bridge saw rental services.

Delivery and Pickup: Understand the logistics surrounding equipment delivery and pickup. Some companies may charge additional fees for these services, while others incorporate them in the leasing cost, affecting your total expenses.

Being well-informed about these terms will empower you to manage your budget effectively and avoid unexpected expenses during your leasing experience. Expert opinions indicate that proactive communication with leasing firms can mitigate risks and enhance project efficiency. Additionally, common pitfalls such as misestimating rental duration or failing to clarify maintenance responsibilities should be avoided to ensure a successful rental experience.

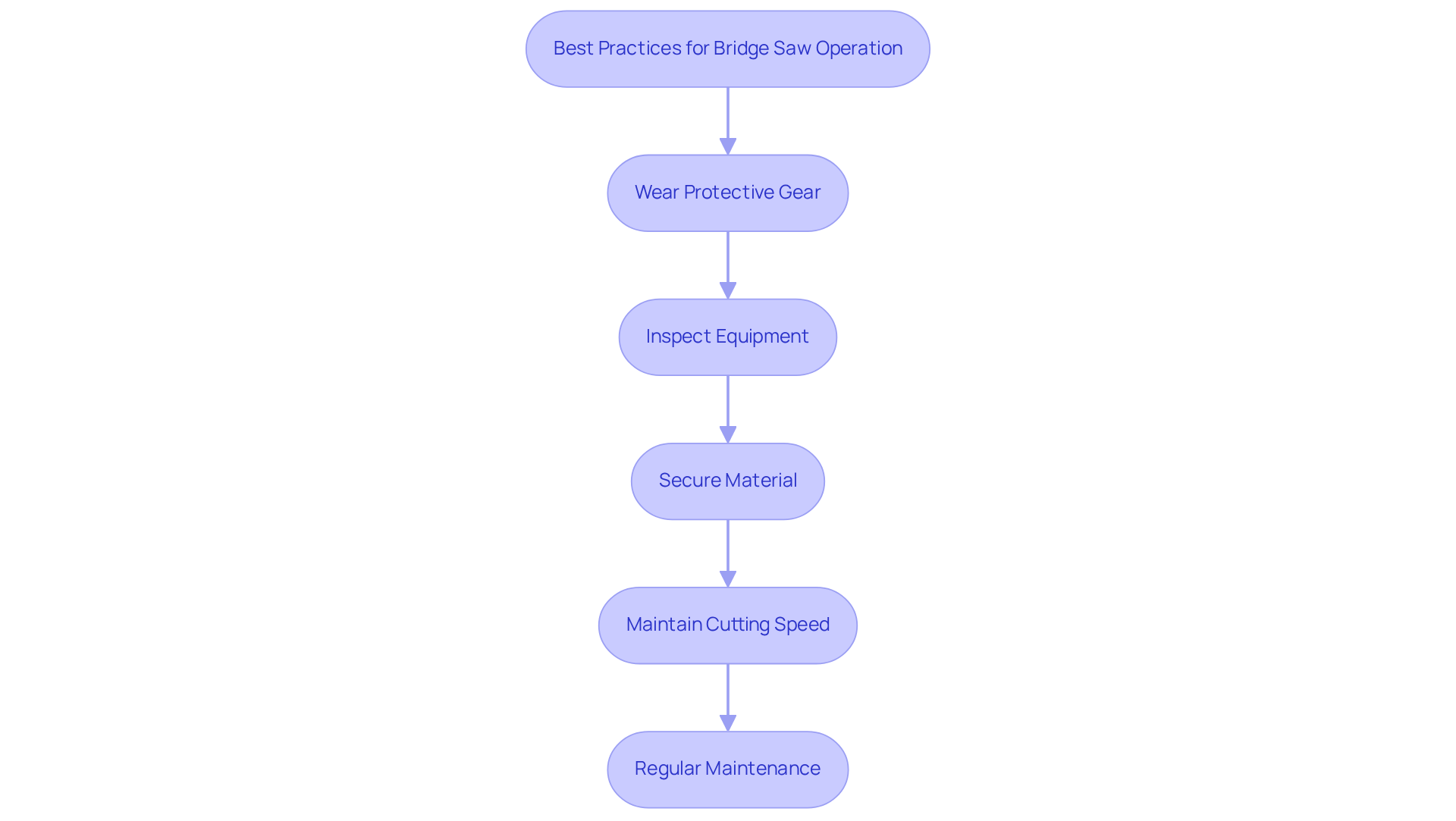

Implement Best Practices for Safe and Efficient Operation

To ensure the safe and efficient operation of your bridge saw, it is imperative to adhere to the following best practices:

-

Wear Protective Gear: Always don appropriate safety attire, including goggles, gloves, and ear protection. This gear is essential for safeguarding against potential hazards. Safety professionals emphasize that proper protective measures are crucial in preventing injuries. As Jeff Cooper aptly stated, "Safety is something that happens between your ears, not something you hold in your hands."

-

Inspect the bridge saw rental equipment thoroughly before use to ensure it is safe for operation. Look for any signs of wear or damage, particularly on the blade and electrical components. Routine inspections of tools, such as bridge saw rental equipment, are essential in the construction sector to uphold safety standards and avert accidents. Remember, nearly 40,000 circular saw accidents occur annually in the U.S. Army, underscoring the importance of these inspections.

-

Secure the Material: Ensure that the material being cut is firmly positioned on the cutting table. This prevents movement during operation, which can lead to inaccurate cuts or accidents. Properly securing materials is a fundamental practice that enhances both safety and precision.

-

Maintain Proper Cutting Speed: Adjust the cutting speed based on the material being cut. Operating too quickly can result in chipping or blade damage, while cutting too slowly may reduce efficiency. Understanding the optimal speed for different materials is key to effective operation.

-

Regular maintenance for the bridge saw rental involves following the manufacturer's guidelines, which include cleaning the saw and checking the water system to prevent overheating. Consistent maintenance ensures optimal performance and longevity of the equipment.

By adhering to these practices, you significantly enhance safety and efficiency during your project, leading to improved outcomes and reduced risks. Additionally, be aware of common pitfalls such as inadequate training or reliance solely on safety mechanisms without understanding their proper use.

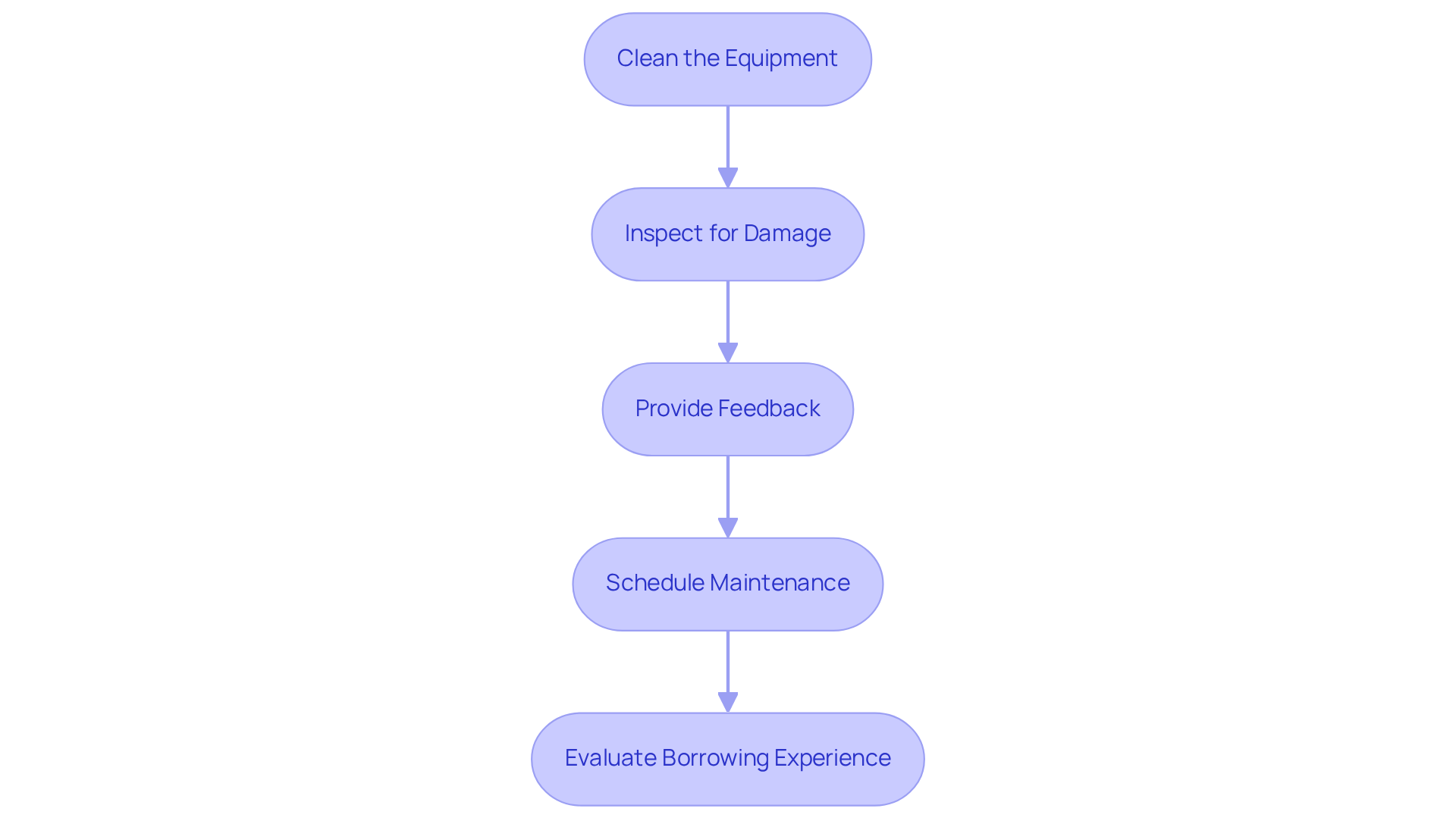

Follow Up with Maintenance and Feedback After Rental

Upon completing your rental, it is crucial to consider the following essential steps:

-

Clean the Equipment: Begin by thoroughly cleaning the bridge saw rental to remove any debris or residue from the cutting process. Regular cleaning not only preserves the condition of the apparatus but also extends its lifespan by reducing the risk of corrosion and rust.

-

Inspect for Damage: Next, carefully examine the saw for any signs of damage that may have occurred during your borrowing period. Document any issues, as 44% of companies identify outdated machinery as a significant cause of unexpected downtime. This documentation will be vital for discussions with the leasing company. Additionally, keep in mind that an hour of equipment downtime costs businesses an average of $260,000, underscoring the importance of inspections in minimizing financial losses.

-

Provide Feedback: It is also beneficial to share your experience with the leasing company, including any encountered issues or suggestions for improvement. Feedback is essential for enhancing service quality, and many leasing firms value insights from their customers to refine their operations. As one leasing company noted, "Regular feedback helps us enhance our services and ensure customer satisfaction."

-

Schedule Maintenance: If you plan to rent the saw again in the future, consider scheduling maintenance with the leasing company. This proactive approach ensures that the tools are in optimal condition for your next task, adhering to best practices of preventive maintenance that can significantly reduce downtime.

-

Evaluate Borrowing Experience: Finally, reflect on your borrowing experience, including the saw's performance and the service provided by the leasing company. This evaluation will aid you in making informed decisions for future leases, ensuring you select tools that meet your needs effectively. Be mindful of common pitfalls, such as failing to document damage or feedback, which can hinder the leasing process.

By following these steps, you not only enhance the overall quality of the leasing service but also contribute to ensuring that the equipment remains reliable for future projects. Regular maintenance and feedback not only improve your experience but also support the rental company's commitment to excellence.

Conclusion

Selecting the right bridge saw rental is essential for achieving optimal results in any stone fabrication project. By thoroughly evaluating project specifications, blade compatibility, motor power, cutting capacity, and portability, one can ensure that the chosen saw meets the specific demands of the task. Understanding these critical factors enhances efficiency and minimizes the risk of costly errors that can occur from using unsuitable equipment.

This article has provided key insights into the importance of understanding rental terms and conditions, adhering to best practices for safe operation, and following up with maintenance and feedback after the rental period. Each aspect—ranging from lease duration to equipment inspection and proactive communication with rental companies—plays a vital role in ensuring a smooth and successful experience. This comprehensive approach highlights the interconnected nature of these practices and their collective impact on project outcomes.

Ultimately, maximizing a bridge saw rental transcends merely selecting the right equipment; it requires a commitment to safety, efficiency, and continuous improvement. By implementing these best practices, individuals and companies can enhance their immediate project performance while contributing to the long-term reliability and success of their operations. Engaging with rental companies through feedback and maintenance schedules fosters a culture of collaboration and quality, ensuring that both parties benefit from a positive rental experience.

Frequently Asked Questions

What should I consider when selecting a bridge saw rental for my project?

You should assess the materials you will be cutting (granite, marble, or tile), their thickness, the compatibility of the saw with the required blade size and type, the motor power, the maximum cutting depth and angle capabilities, and the portability of the saw.

Why is it important to assess the materials and thickness I will be cutting?

Each saw is engineered for specific materials and thicknesses, which directly affects cutting efficiency and quality. Choosing the right saw for your materials ensures better performance.

How does blade size and type affect the selection of a bridge saw?

The blade size and type must be compatible with the saw for the task. Larger blades can handle thicker materials but may require more power to operate effectively.

What role does motor power play in the performance of a bridge saw?

A robust motor is essential for efficient cutting, especially with dense materials. Higher horsepower ratings are recommended for heavy-duty applications.

What is meant by cutting capacity in the context of bridge saws?

Cutting capacity refers to the saw's maximum cutting depth and angle capabilities, which are important to ensure the saw can handle various cutting tasks required for your project.

How important is portability when choosing a bridge saw?

If your project requires frequent relocation of the saw, portability is crucial. Some models are designed with wheels for enhanced mobility, making them easier to maneuver on job sites.

What are the financial implications of using a bridge saw?

While bridge cutting tools require a considerable initial expenditure, they can lead to savings through decreased waste and lower labor expenses over time, making them a financially viable option.

Why is it important to choose high-quality tools for bridge sawing?

High-quality tools prevent costly errors and wasted resources, as low-quality machines can lead to inefficiencies and subpar results.

How can insights from construction professionals assist in selecting a bridge saw?

Insights from professionals can guide your selection process by providing practical advice and highlighting the importance of choosing the appropriate saw for specific applications, such as stone fabrication.

What should I do to avoid pitfalls when selecting a bridge saw rental?

Thoroughly evaluate the key factors mentioned, consider the potential pitfalls of selecting unsuitable machines, and ensure that the saw aligns with your project specifications for superior results and efficient operation.