Key Highlights:

- Articulating boom lifts, or knuckle platforms, are designed for accessing challenging elevated work areas with articulated segments for manoeuvrability.

- Key features include versatility for navigating obstacles, working heights of 10 to 20 metres, and stability enhancements through stabilisers.

- The market for articulating aerial platforms is projected to grow from USD 12.4 billion in 2024 to USD 19.6 billion by 2033, driven by increased construction activities.

- Selecting the right boom lift involves assessing project requirements, site conditions, power sources, and budget considerations.

- Average rental prices for articulating boom lifts in Texas range from $200 to $500 per day, with rentals accounting for 93.5% of global revenue in 2021.

- Best practises for safe operation include conducting pre-operation checks, using PPE, monitoring weather conditions, and maintaining clear communication among team members.

- Regular maintenance practises such as inspections, fluid checks, and professional servicing are crucial for ensuring optimal performance and safety.

Introduction

Boom lifts are essential tools in the construction industry, providing unparalleled access to challenging and elevated workspaces. Their unique design enables operators to navigate around obstacles with ease, making them indispensable for a variety of tasks, from maintenance to complex installations. However, the effectiveness of these machines depends on:

- A thorough understanding of their features

- Selecting the right model for specific project needs

- Adhering to best practices for safe operation

What challenges arise when trying to maximize the efficiency and safety of these lifts? Project managers must consider how to ensure they are making the best choices for their teams. By addressing these questions, we can better appreciate the role of boom lifts in enhancing productivity and safety on construction sites.

Understand Articulating Boom Lifts: Definition and Features

Articulating cranes, often called knuckle platforms, are specialized aerial work structures designed to provide access to challenging and elevated work locations. These hoists feature several articulated segments that allow the arm to flex and extend, facilitating maneuverability around obstacles and precise placement in complex work environments. Key features include:

- Versatility: Articulating boom lifts excel at navigating over and around obstacles, making them essential for intricate construction tasks, such as installing skylights or lifting HVAC units onto rooftops. Their unique capabilities are particularly advantageous in urban development, where construction projects in Dallas are common.

- Height and Reach: With working heights ranging from 10 to 20 meters and horizontal reach capabilities between 3 to 12 meters, these machines are vital for various applications, including maintenance and construction. This exceptional reach enables workers to safely and efficiently access elevated areas, whether for painting, repairs, or facade maintenance in high-rise buildings.

- Stability: Many models come equipped with stabilizers or outriggers, enhancing security and stability during operation. This feature is crucial in environments where employee safety is paramount, as articulated aerial platforms significantly reduce the risk of accidents.

Recent advancements in aerial platform technology, including electric and hybrid variants, address environmental concerns while expanding application possibilities. The market for articulating aerial platforms was valued at USD 12.4 billion in 2024 and is projected to grow to USD 19.6 billion by 2033, reflecting a CAGR of 5.18% during this period, driven by increasing construction activities and a focus on efficient material handling.

Case studies highlight the effectiveness of articulating aerial platforms in enhancing operational efficiency. For example, their unique 'up and over' capabilities allow operators to position the basket over obstacles, providing greater versatility in various work settings. As articulating boom lifts continue to evolve, their role in construction and maintenance becomes increasingly vital, highlighting the importance of selecting the right tools for specific needs. Renting hoists from EZ Equipment Rental ensures that construction managers have access to top-quality equipment for their elevated work tasks.

Select the Right Boom Lift for Your Project Needs

Selecting the right articulating boom lift is essential for the success of any project, and it involves several key considerations:

-

Project Requirements: Clearly define the necessary height and reach for your tasks. Assess the weight capacity required for both personnel and equipment, as this directly impacts operational efficiency.

-

Site Conditions: Examine the terrain and identify any barriers that could hinder hoisting operations. For instance, when working on uneven surfaces, choosing a model equipped with stabilizers can significantly enhance safety and performance.

-

Power Source: Decide between electric and diesel-powered lifts based on the specific work environment. Electric lifts are ideal for indoor applications due to their low emissions, while diesel models excel in outdoor settings where strength and durability are paramount.

-

Budget Considerations: Evaluate the costs associated with renting versus purchasing. While renting may offer short-term flexibility, investing in a lift that meets your long-term needs can yield substantial benefits over time.

In Texas, the average rental price for articulating boom lifts typically ranges from $200 to $500 per day, depending on the model and specifications. This cost-effectiveness is a significant factor driving the rental market, which accounted for approximately 93.5% of global revenue in 2021. By thoroughly assessing these factors, managers can make informed decisions that enhance productivity and safety on the job site, ultimately leading to successful project outcomes.

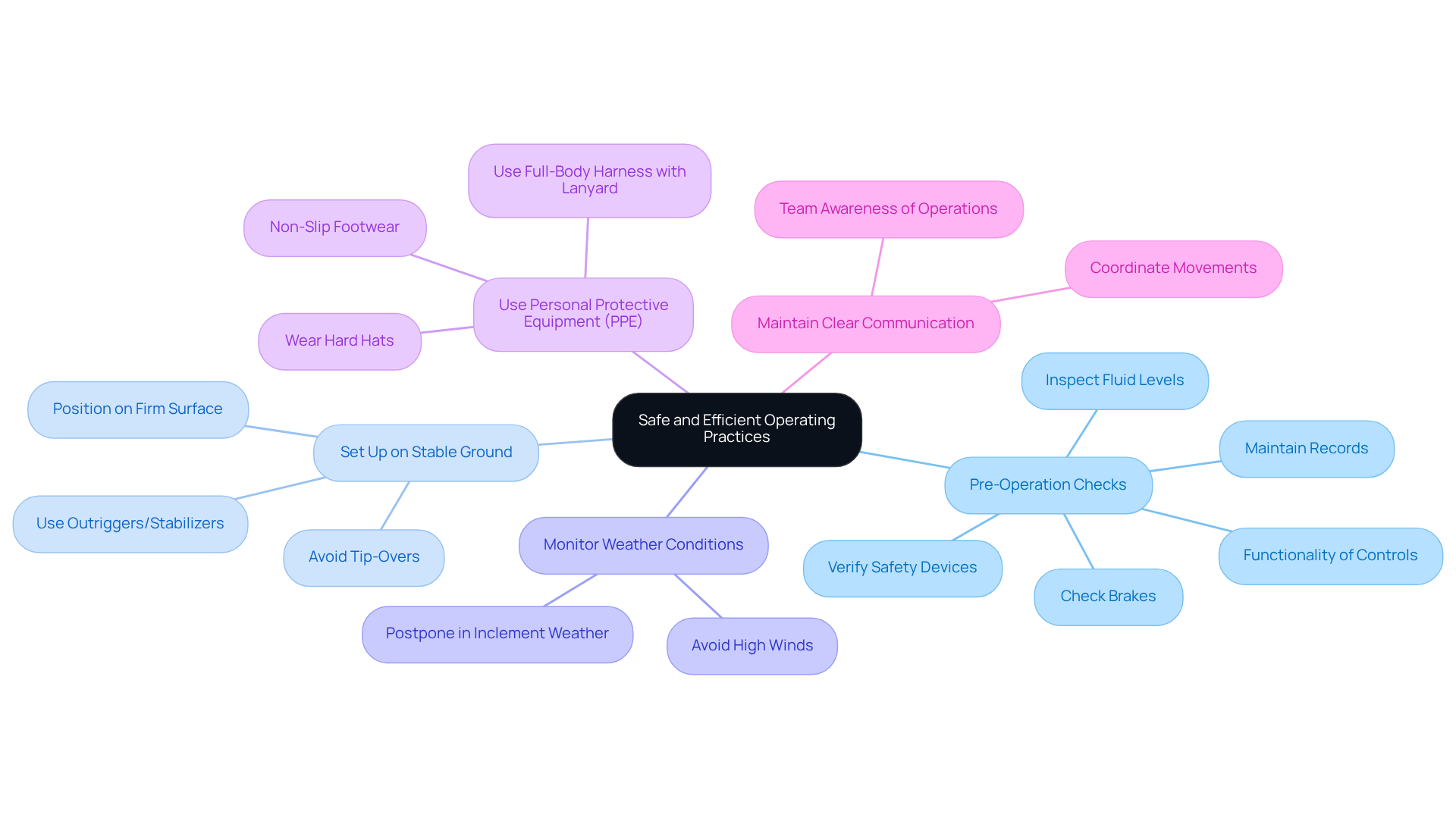

Implement Safe and Efficient Operating Practices

To operate articulating boom lifts safely and efficiently, particularly in the context of Dallas's thriving construction projects, it is essential to adhere to the following best practices:

-

Pre-Operation Checks: Conduct thorough inspections before use, including checking fluid levels, brakes, and safety devices. Ensure that all controls are functioning properly. Regular maintenance records are crucial for compliance with OSHA regulations.

-

Set Up on Stable Ground: Always position the apparatus on a firm, level surface. Employ outriggers or stabilizers to enhance stability, as improper setup is a leading cause of tip-overs, which account for a significant portion of aerial equipment fatalities.

-

Monitor Weather Conditions: Avoid operating lifts in high winds or adverse weather conditions that could compromise safety. Aerial devices should not be used in inclement weather until conditions improve to prevent accidents.

-

Use Personal Protective Equipment (PPE): Operators must wear appropriate PPE, including hard hats, harnesses, and non-slip footwear. The use of a full-body harness with a lanyard is mandatory to mitigate fall risks, as falls are a leading cause of injuries in aerial equipment operations. According to OSHA, "the primary causes include falls, electrocutions (including power lines), falling objects, collapses, equipment tip-overs, and even ejections from the boom platform."

-

Maintain Clear Communication: Ensure that all team members are aware of the lift's operation and maintain clear communication throughout the task. This practice is vital for coordinating movements and preventing accidents, especially in busy work environments.

By following these practices, operators can significantly reduce the risk of accidents involving articulating boom lifts, which account for approximately 2-3% of all construction deaths annually. Furthermore, non-compliance with safety regulations can lead to fines and penalties exceeding $20,000, providing a strong incentive to adhere to these protective measures. Given the critical role of aerial platforms in urban development, renting from EZ Equipment Rental ensures access to well-maintained machinery that complies with safety regulations, thereby enhancing project success.

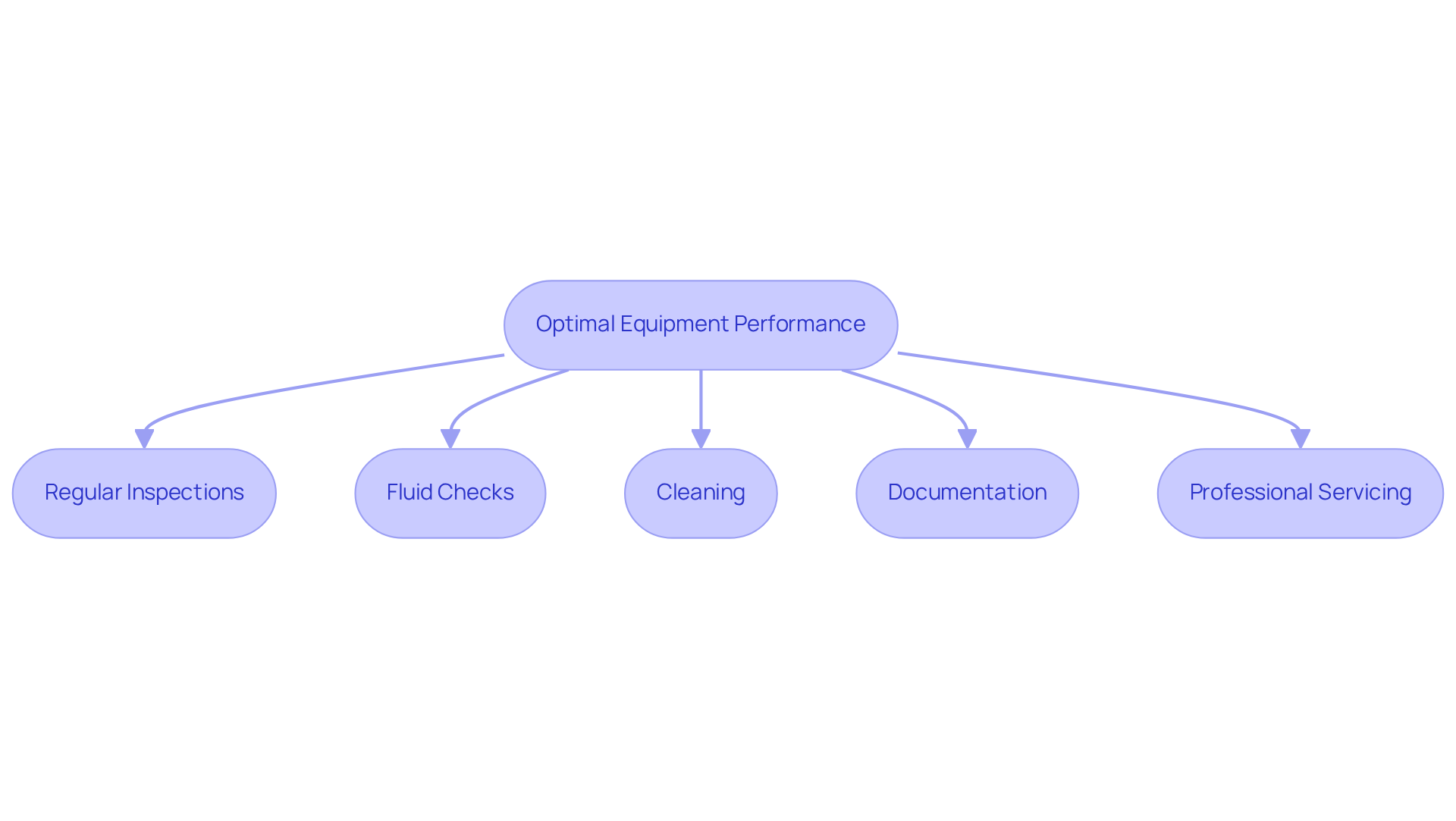

Maintain Equipment for Optimal Performance

To ensure articulating boom lifts operate at peak performance, it is essential to implement the following maintenance practices:

-

Regular Inspections: Schedule routine inspections to assess wear and tear, focusing on hydraulic systems, electrical components, and safety features. This proactive approach significantly reduces the risk of malfunctions, as regular checks are crucial for identifying potential issues early.

-

Fluid Checks: Consistently monitor and replace hydraulic fluids, oil, and filters according to the manufacturer's recommendations. This practice is vital for preventing system failures and can prolong the lifespan of the elevator by as much as 20%, underscoring the significance of proper maintenance.

-

Cleaning: Maintain a clean lift to prevent rust and corrosion. Regularly removing dirt and debris from moving parts and surfaces not only enhances performance but also contributes to the longevity of the equipment.

-

Documentation: Keep a detailed log of all maintenance activities, including inspections, repairs, and replacements. This documentation aids in identifying recurring issues and informs future maintenance strategies, ensuring a systematic approach to equipment care.

-

Professional Servicing: Engage qualified technicians for complex repairs and maintenance to ensure adherence to standards and manufacturer guidelines. Professional oversight is essential for preserving the integrity of protective features, which, according to OSHA, can decrease workplace accidents by approximately 60%.

By adhering to these maintenance practices, operators can extend the lifespan of their articulating boom lifts, ensuring reliable performance during the execution of the task. Regular maintenance not only enhances safety but also maximizes operational efficiency, making it a critical component of successful project management.

Conclusion

In conclusion, articulating boom lifts are essential tools in construction and maintenance, providing vital access to challenging elevated workspaces. Their unique design, characterized by flexibility and reach, enables operators to navigate obstacles effectively, ensuring both efficiency and safety across various applications. Understanding their features and capabilities is crucial for maximizing their potential and achieving successful project outcomes.

This article has highlighted key considerations for selecting and operating articulating boom lifts. From assessing project requirements and site conditions to implementing safe operating practices and maintaining equipment, each aspect plays a significant role in enhancing productivity and minimizing risks. The importance of thorough pre-operation checks, clear communication among team members, and adherence to maintenance schedules cannot be overstated, as these practices greatly contribute to operational safety and efficiency.

Given these insights, it is imperative for construction managers and operators to prioritize the selection of the appropriate boom lift and commit to best practices in their operation and maintenance. By doing so, they can ensure the safety of their teams while enhancing the overall success of their projects. Investing time in understanding and applying these best practices will lead to improved performance, reduced accidents, and ultimately, a more successful and efficient work environment.

Frequently Asked Questions

What are articulating boom lifts?

Articulating boom lifts, also known as knuckle platforms, are specialized aerial work structures designed to provide access to challenging and elevated work locations through articulated segments that allow the arm to flex and extend.

What are the key features of articulating boom lifts?

Key features include versatility for navigating obstacles, working heights ranging from 10 to 20 meters with horizontal reach capabilities of 3 to 12 meters, and stability enhancements such as stabilizers or outriggers.

How do articulating boom lifts enhance versatility in construction?

They excel at maneuvering over and around obstacles, making them essential for intricate construction tasks like installing skylights or lifting HVAC units onto rooftops, particularly in urban development.

What is the importance of stability in articulating boom lifts?

Stability is crucial for employee safety, as many models are equipped with stabilizers or outriggers that reduce the risk of accidents during operation.

What advancements are being made in aerial platform technology?

Recent advancements include the development of electric and hybrid variants that address environmental concerns and expand application possibilities.

What is the market outlook for articulating aerial platforms?

The market was valued at USD 12.4 billion in 2024 and is projected to grow to USD 19.6 billion by 2033, reflecting a CAGR of 5.18%, driven by increasing construction activities and a focus on efficient material handling.

How do articulating boom lifts improve operational efficiency?

Their unique 'up and over' capabilities allow operators to position the basket over obstacles, providing greater versatility in various work settings, which enhances operational efficiency.

Why is it important to select the right tools for specific needs in construction?

Selecting the right tools, such as articulating boom lifts, is vital for ensuring safety and efficiency in construction and maintenance tasks. Renting quality equipment, like those from EZ Equipment Rental, can help construction managers meet their elevated work needs.

List of Sources

- Understand Articulating Boom Lifts: Definition and Features

- Are Boom Lifts the Secret Weapon of Construction Sites? (https://skyblackrentals.com/skyblog/construction-experts/articulating-boom-lifts-secret-weapon-of-construction-sites?srsltid=AfmBOoqrVfTWCKRdt-zA1HtPUHBwq8mhewqHxpGmbGCaFUInwxp5juWS)

- Boom Lifts Market Size, Share And Forecast Report, 2033 (https://imarcgroup.com/boom-lifts-market)

- The 5 Benefits of Articulated Boom Lifts | Concord Access Solutions (https://concordaccesssolutions.com/the-5-benefits-of-articulated-boom-lifts)

- Articulated Boom Lifts Market Analysis 2026, Market Size, Share, Growth, CAGR, Forecast, Trends, Revenue, Industry Experts, Consultation, Online/Offline Surveys, Syndicate Reports (https://cognitivemarketresearch.com/articulated-boom-lifts-market-report)

- Select the Right Boom Lift for Your Project Needs

- Boom Lift Market Report: Trends, Forecast and Competitive Analysis to 2030 (https://lucintel.com/boom-lift-market.aspx)

- Boom Lifts Market Size, Share, Trends & Growth Report, 2030 (https://grandviewresearch.com/industry-analysis/boom-lifts-market-report)

- Boom Lifts Market Size, Share And Forecast Report, 2033 (https://imarcgroup.com/boom-lifts-market)

- Rise Above the Basics When Selecting Boom Lifts for Construction Applications (https://forconstructionpros.com/rental/lifting-equipment/boom-lift/article/12245420/rise-above-the-basics-when-selecting-boom-lifts-for-construction-applications)

- Boom Lifts Market Size, Share & Global Industry 2035 (https://marketresearchfuture.com/reports/boom-lifts-market-27050)

- Implement Safe and Efficient Operating Practices

- Aerial Lift Hazards and What to Watch Out For 2026 (https://certifymeonline.net/blog/top-5-aerial-lift-hazards-avoid)

- How Do Accidents Happen on Aerial Lifts? (https://aerialliftcertification.com/blog/accidents-happen-aerial-lifts)

- eLCOSH : Deaths From Aerial Lifts (https://elcosh.org/document/1417/d000484/deaths-from-aerial-lifts.html)

- IPAF Global Safety Report 2024 | IPAF (https://ipaf.org/en-us/gsr2024)

- Aerial Lift & Scissor Lift Accidents & Safety - Rentalex (https://rentalex.com/aerial-lift-scissor-lift-accidents-safety)

- Maintain Equipment for Optimal Performance

- What is the lifespan of a boom lift? - Blog - OUCO Heavy (https://oucomarine-group.com/blog/what-is-the-lifespan-of-a-boom-lift-749506.html)

- What is the lifespan of an articulated boom lift? (https://fstlift.com/news/what-is-the-lifespan-of-an-articulated-boom-lift.html)

- How often should an Articulating Boom Lift be serviced? - Blog (https://scissor-lifting.com/blog/how-often-should-an-articulating-boom-lift-be-serviced-1798066.html)

- What You Must Know When You Buy a Boom Lift (https://certifymeonline.net/blog/things-to-consider-when-purchasing-boom-lift)

- Boom Lift Maintenance: Tips to Extend the Life of Your Aerial Work Platform | EquipmentShare (https://equipmentshare.com/articles/boom-lift-maintenance-tips-to-extend-the-life-of-your-aerial-work-platform)