Overview

Vapor abrasive blasting rental in Dallas, TX, presents significant advantages over traditional methods. This innovative approach not only reduces dust emissions but also delivers superior surface finishes, making it an ideal choice for a variety of industrial applications. The method's effectiveness is underscored by its ability to minimize health risks and enhance cleaning efficiency by up to 96.9%.

Furthermore, selecting reputable rental providers, such as EZ Equipment Rental, is crucial as they prioritize quality and exceptional customer service, ensuring a reliable experience for users.

Key Highlights:

- Vapor abrasive blasting combines water and abrasive materials, reducing dust and environmental impact.

- This method is gaining popularity in sectors like automotive restoration and industrial cleaning due to its superior surface finishes.

- Despite the reduction in dust, vapor blasting still requires adherence to air quality control measures.

- OSHA regulations aim to protect workers from exposure to harmful silica dust during abrasive blasting.

- Vapor blasting offers a smoother finish, is gentler on materials, and can reduce cleaning time by up to 96.9%.

- EZ Equipment Rental in Dallas offers competitive rental rates and flexible terms for vapor abrasive blasting equipment.

- Key factors for selecting a rental service include equipment quality, customer support, and pricing structures.

- Common inquiries about vapor blasting include its versatility on surfaces, safety equipment needs, and the selection of appropriate abrasive media.

- The construction industry represents a significant market for sand blaster rentals, indicating growing demand for effective cleaning solutions.

Introduction

In the realm of surface preparation, vapor abrasive blasting stands out as a revolutionary technique. By seamlessly blending water with abrasive materials, it delivers superior cleaning and finishing results. This innovative method not only reduces dust emissions but also minimizes environmental impact, making it a preferred choice in sensitive settings. As industries increasingly prioritize compliance and sustainability, understanding the advantages of vapor abrasive blasting becomes essential for project managers who seek efficient and effective solutions.

From automotive restoration to industrial cleaning, this approach offers a compelling alternative to traditional blasting methods. It paves the way for enhanced surface quality and operational efficiency. As the demand for environmentally friendly practices grows, so does the necessity for informed decisions when selecting rental services in bustling markets like Dallas. By choosing vapor abrasive blasting, organizations can ensure they are making a responsible choice that aligns with their sustainability goals.

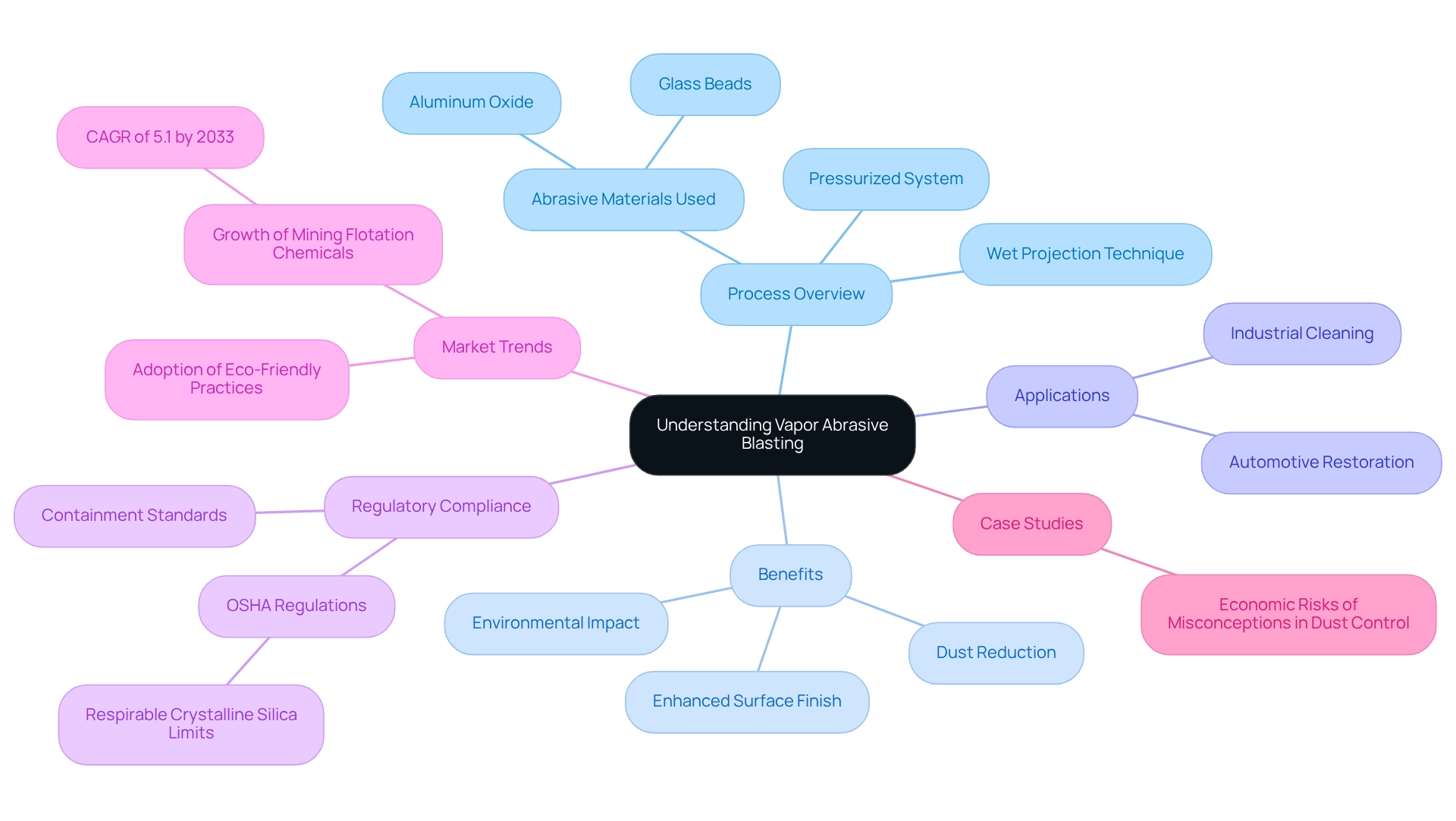

Understanding Vapor Abrasive Blasting: An Overview

Vapor media projection, commonly referred to as wet projection, represents a sophisticated surface preparation method that effectively combines water with abrasive materials to clean and finish surfaces. This innovative technique significantly reduces dust generation and minimizes environmental impact, making it particularly beneficial for sensitive environments. Utilizing a pressurized system, this method mixes water with various abrasive materials, such as glass beads or aluminum oxide, which are then propelled onto the target surface.

This approach is gaining traction across diverse sectors, including automotive restoration and industrial cleaning, due to its ability to deliver superior surface finishes while being gentler than traditional dry methods. Importantly, vapor-based surface treatment not only enhances surface quality but also plays a crucial role in dust management, countering the common misconception that this process is dust-free. In reality, all explosive procedures produce some level of dust, and the use of mist-based systems does not exempt contractors from adhering to air quality control measures and containment requirements.

According to OSHA, the final rule was established to reduce the risks of lung cancer, silicosis, chronic obstructive pulmonary disease, and kidney disease among America’s workforce by limiting exposure to respirable crystalline silica. A pertinent case study illustrates the economic risks associated with misconceptions in dust control, highlighting that contractors who mistakenly believe that investing in dust-eliminating equipment will exempt them from regulatory compliance may incur substantial penalties. This underscores the necessity for all vapor-based erosion systems to comply with established containment standards, irrespective of their perceived effectiveness in minimizing dust.

In summary, vapor-based erosion techniques emerge as a versatile and eco-friendly choice for surface preparation, offering numerous advantages such as reduced dust emissions and enhanced surface finishes. As industries increasingly prioritize compliance and environmental responsibility, the adoption of this technique is projected to rise, aligning with broader market trends that emphasize sustainable practices. Notably, the market trend for mining flotation chemicals is expected to grow at a CAGR of 5.1% by 2033, indicating a rising demand for efficient and compliant surface preparation techniques like vaporized particulate methods.

For construction project managers in Dallas, TX, exploring equipment rental options, in Dallas, TX, presents an attractive solution that meets both operational and regulatory requirements.

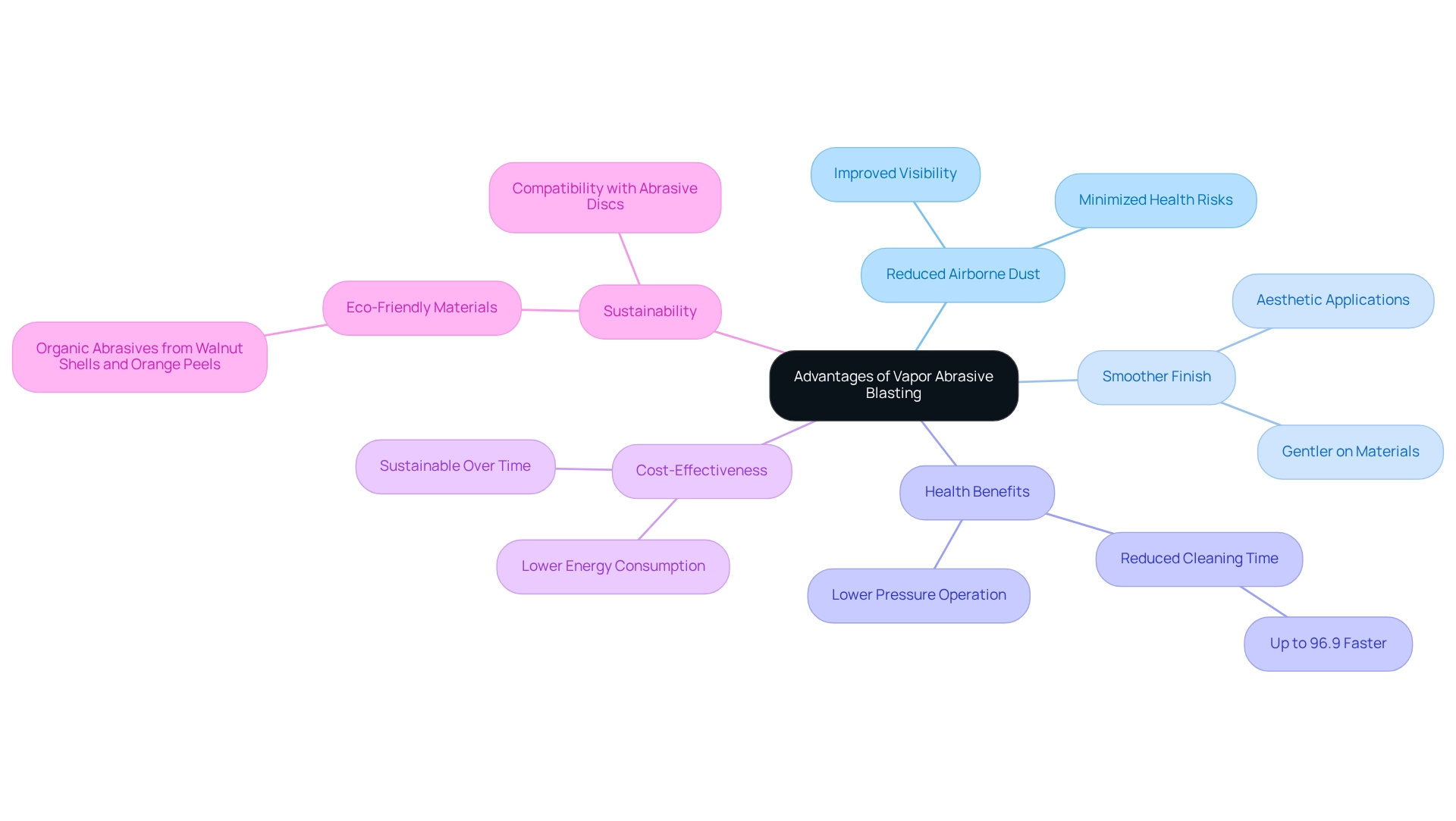

Advantages of Vapor Abrasive Blasting Compared to Traditional Methods

Vapor abrasive blasting rental in Dallas, TX, presents numerous advantages over traditional dry techniques, establishing itself as a preferred choice for a variety of applications. A primary benefit is the significant reduction in airborne dust, which not only improves visibility on job sites but also minimizes health risks for workers. By incorporating water into the blasting process, mist cleaning effectively captures , preventing it from dispersing and causing environmental contamination.

Furthermore, vapor surface treatment results in a smoother finish on surfaces, particularly beneficial for applications where aesthetics are paramount, such as automotive refinishing. This method is also gentler on materials, substantially reducing the risk of damage to delicate surfaces. As highlighted by B. Ś., "the aim of the work... was to draw attention to its effect on grain embedding, which may influence any subsequent bond formed with ceramics," underscoring the importance of material compatibility in explosive processes.

The health benefits of vapor-based cleaning are remarkable; it can reduce cleaning time by as much as 96.9% compared to conventional methods, facilitating more efficient project completion. Moreover, equipment that operates at lower pressures and consumes less energy is not only more sustainable but also more cost-effective over time. The development of organic materials from walnut shells and orange peels, as demonstrated in a case study, emphasizes the potential for eco-friendly alternatives in material removal, further strengthening the sustainability argument.

In conclusion, the combination of reduced dust, improved surface finishes, and enhanced health and environmental safety positions high-pressure cleaning as a superior choice for various industrial applications, including vapor abrasive blasting rental in Dallas, TX. Additionally, understanding the hardness of materials, such as zirconium oxide being rated at 1432 HV, provides valuable context for selecting the appropriate method for different surfaces.

Top Vapor Abrasive Blasting Rental Providers in Dallas: A Comparative Analysis

In Dallas, numerous suppliers offer vapor abrasive blasting rental services, yet EZ Equipment Rental stands out as a premier choice. With a competitive daily lease rate of $130 for treatment equipment, EZ Equipment Rental emphasizes flexible terms and a steadfast commitment to customer satisfaction. This makes it an appealing option for construction project managers. Our store hours are tailored to your convenience:

- Monday to Friday from 7:30 AM to 5:30 PM

- Saturday from 7:30 AM to 5:00 PM

This ensures you can access our services when it suits you best.

The construction industry is poised to dominate the global sand blaster rental market, holding a remarkable share of 43.2% in 2023, underscoring the increasing demand for . As Nikhil Kaitwade, Principal Consultant, notes, "The cleaning equipment is being increasingly utilized in aviation production and MRO for remanufacturing jets, auxiliary power units, and landing gear components." This observation highlights the adaptability and growing significance of cleaning machinery that employs vapor across various sectors.

When selecting a leasing provider, it is crucial to consider factors such as equipment availability, leasing terms, and customer reviews. EZ Equipment Rental’s dedication to customer satisfaction, competitive pricing, and accessible store hours positions it as a leading provider of vapor abrasive blasting rental in Dallas, TX, ensuring that specific project needs are met effectively. Stay connected with us through our social media channels on Facebook, Instagram, Twitter, and YouTube for updates and engagement.

Key Considerations When Selecting a Vapor Abrasive Blasting Rental Service

Choosing a vapor abrasive blasting rental service in Dallas, TX, requires a thoughtful evaluation of several critical factors. First and foremost, assessing the quality and condition of the equipment is essential. Well-maintained machines are crucial for achieving optimal blasting results, as they ensure efficiency and effectiveness across various applications.

Preventive maintenance compliance should be at least 90% to sustain equipment performance and reliability. Furthermore, understanding the leasing terms for vapor abrasive blasting rentals is vital; this includes examining pricing structures and the flexibility of leasing durations to accommodate project timelines. Budget constraints are a common challenge, with 37.2% of maintenance supervisors citing this as a concern over the past five years. Therefore, locating a provider that offers competitive pricing without compromising quality is imperative.

Customer support significantly impacts the leasing experience. A responsive and knowledgeable team can provide invaluable assistance, addressing concerns and ensuring users maximize the equipment's potential. Additionally, it is crucial to inquire about the availability of different abrasive media options. A trustworthy provider should offer guidance on selecting the appropriate media tailored to specific project needs.

Lastly, evaluating customer reviews and feedback is essential for determining the reliability and reputation of the service. This understanding helps identify providers that prioritize quality and customer satisfaction, ultimately leading to a more successful leasing experience. Effective communication across departments is also crucial for maintenance management, as illustrated by case studies demonstrating that timely communication fosters collaboration and keeps teams informed on servicing schedules and potential risks.

By focusing on these key considerations, including the importance of user engagement—given that 60-80% of Computerized Maintenance Management System (CMMS) implementations fail due to —project managers can make informed decisions that enhance operational efficiency and project outcomes. Furthermore, it is significant that 52% of industrial facilities utilize a CMMS, underscoring the importance of technology in equipment management and leasing services.

Frequently Asked Questions About Vapor Abrasive Blasting Rentals

Prospective clients frequently inquire about vapor abrasive blasting rental services in Dallas, TX. Key questions often include:

- What types of surfaces can be treated with vapor blasting?

Vapor cleaning is remarkably versatile, effectively treating a variety of surfaces, including metal, wood, and concrete, making it suitable for numerous applications. - How does steam cleaning measure up against conventional sand shooting?

In contrast to traditional sand cleaning, the misting process is gentler and produces significantly less dust. This enhancement not only improves safety but also results in a cleaner finish, thereby reducing post-project cleanup costs. A case study titled "Advantages of Wet Abrasive Blasting" highlights that this method minimizes dust and cleanup expenses while delivering a consistent finish devoid of embedded particles. - What safety equipment is required when using vapor blasting equipment?

Operators must utilize appropriate personal protective equipment (PPE), which includes gloves, goggles, and respiratory protection, to ensure safety during operation. - How do I determine the right abrasive media for my project?

Consulting with the rental provider is essential, as they can assist in identifying the most suitable media based on the specific surface and desired finish, ensuring optimal results.

In addition to these common inquiries, it is crucial to consider the safety data associated with equipment use for vaporizing. Recent studies indicate that blast rooms designed for liquid treatment enhance worker safety by providing ample space for movement and operation, thus minimizing fatigue and the risk of accidents. Furthermore, the available dust collector sizes range from 3000 CFM to 30000 CFM, offering various options for clients contemplating vaporized material rentals.

The advantages of wet material spraying, such as its ability to provide a uniform finish without trapped particles or dust, make it a preferred choice for surface preparation in diverse settings. As noted by BlastKing, "Creating that precisely suits your requirements is akin to locating the correct key for a lock—it must be exactly right," underscoring the importance of customized solutions in the process.

Making the Right Choice for Your Vapor Abrasive Blasting Needs

Selecting the appropriate cleaning service requires a comprehensive understanding of the technique's benefits, a detailed comparison of top providers, and careful consideration of crucial factors such as equipment quality and customer support. The in Dallas, TX, offers numerous advantages, including reduced dust emissions and enhanced surface preparation, making it an ideal choice for industrial cleaning and restoration projects.

When evaluating leasing options, prospective tenants should prioritize providers dedicated to high-quality equipment. The impact of equipment quality on leasing satisfaction cannot be overstated; reliable machinery not only ensures effective project results but also minimizes downtime and maintenance issues. For instance, a case study from a scuba gear leasing business demonstrated that monitoring maintenance costs led to phasing out high-maintenance items, ultimately boosting revenue and equipment availability. This underscores the necessity of tracking equipment performance to enhance operational efficiency.

Customer support is another essential aspect of the leasing experience. A knowledgeable and responsive team can significantly enhance the leasing process, addressing concerns and offering guidance tailored to specific project needs. As Steve Mau, president and owner of Brainerd General Rental, noted, "That’s actually been working well for us," highlighting the critical role of effective customer support in the leasing sector.

Furthermore, as the construction leasing industry grapples with challenges in standardizing services and integrating software with customers' e-procurement systems, the demand for real-time data capture becomes increasingly vital for streamlining operations and improving service delivery.

By making informed choices and understanding the nuances of vapor abrasive blasting rental in Dallas, TX, renters can ensure successful project outcomes and a satisfying experience with the equipment. With the right provider, customers can confidently tackle their industrial cleaning and surface preparation tasks, assured of having the support and quality equipment necessary for success. Notably, industry growth is evident in companies like Flexcavo, which added around 15,000 machines to its operating system before being acquired in January 2023, showcasing the competitive landscape of equipment rental services.

Conclusion

Vapor abrasive blasting stands out as a transformative solution in surface preparation, delivering a unique combination of efficiency, environmental responsibility, and superior results. By integrating water with abrasive materials, this method significantly minimizes airborne dust while enhancing surface finishes. This makes it an ideal choice for a variety of industries, ranging from automotive restoration to industrial cleaning. The focus on sustainability and adherence to environmental regulations further emphasizes the growing significance of this technique in today’s market.

As project managers in Dallas and beyond assess rental options, understanding the key advantages of vapor abrasive blasting is essential. This method not only reduces health risks for workers but also boosts operational efficiency, facilitating quicker project completions. Choosing a dependable rental provider that prioritizes equipment quality and customer support will greatly enhance both the overall experience and project outcomes.

In summary, the transition towards vapor abrasive blasting signifies a commitment to operational excellence and environmental stewardship. By making informed decisions regarding rental services and recognizing the benefits of this innovative blasting technique, organizations can align their practices with sustainability goals while ensuring high-quality surface preparation. The rising demand for responsible and effective solutions in the construction and cleaning sectors indicates a promising future for vapor abrasive blasting as a standard practice in surface preparation.

Frequently Asked Questions

What is vapor media projection, and how does it work?

Vapor media projection, also known as wet projection, is a surface preparation method that combines water with abrasive materials to clean and finish surfaces. It utilizes a pressurized system to mix water with abrasives like glass beads or aluminum oxide, which are then propelled onto the target surface.

What are the benefits of using vapor abrasive blasting?

Vapor abrasive blasting significantly reduces airborne dust, improves visibility on job sites, minimizes health risks for workers, and results in smoother surface finishes. It is particularly beneficial for applications requiring aesthetic quality, such as automotive refinishing, and is gentler on materials, reducing the risk of damage.

How does vapor abrasive blasting impact dust generation?

While vapor abrasive blasting reduces dust emissions, it does not eliminate them entirely. All explosive procedures produce some dust, and contractors must still comply with air quality control measures and containment requirements.

What are the health and economic implications of vapor abrasive blasting?

Vapor-based cleaning can reduce cleaning time by up to 96.9% compared to conventional methods, enhancing project efficiency. However, misconceptions about dust control can lead to significant penalties for contractors if they believe investing in dust-eliminating equipment exempts them from regulatory compliance.

Why is compliance with containment standards important for vapor-based erosion systems?

Compliance with established containment standards is crucial because vapor-based erosion systems, despite their effectiveness in minimizing dust, must adhere to regulations to ensure worker safety and environmental protection.

What is the market trend for vapor abrasive blasting and related technologies?

The adoption of vapor-based erosion techniques is expected to rise as industries prioritize compliance and environmental responsibility. The market for mining flotation chemicals, a related sector, is projected to grow at a CAGR of 5.1% by 2033, indicating increasing demand for efficient surface preparation techniques.

What are some eco-friendly alternatives in vapor abrasive blasting?

The development of organic materials from sources like walnut shells and orange peels showcases the potential for eco-friendly alternatives in material removal, enhancing the sustainability of vapor abrasive blasting methods.

Where can construction project managers in Dallas, TX find vapor abrasive blasting rental options?

Construction project managers in Dallas, TX can explore vapor abrasive blasting rental options to meet operational and regulatory requirements effectively.